Description

Mack E7 E-Tech Diesel Engine Service Manual

Covers: Mack E7 E-Tech Engines w/ electronic unit pump

- 5-101 E7

- 5-106 E-Tech™

- 5-107 E7G

- 5-110 ASET™ AI/AMI

- 5-111 ASET™ AC

Pages: 365

Format: PDF

Size: 34mb

Language: English

Requirements: Adobe PDF Reader & WinZip

Compatibility: All Versions of Windows & Mac/IPAD

Covers mechanical repair, overhaul and basic troubleshooting of the Mack E7 E-Tech engines equipped with an electronic unit pump. V-Mac III troubleshooting sold separately.

TABLE OF CONTENTS:

INTRODUCTION

DESCRIPTION & OPERATION

E-TECH ENGINE DESIGN FEATURES

Electronic Unit Pumps

Belt Drive System

J-Tech Engine Brake

Camshaft

Valve Train

Low-Pressure Fuel System

Fuel Filtration System

High-Pressure Fuel System

High-Pressure Fuel Injection Lines

Fuel Injector Assemblies

Cylinder Block

Crankshaft

Block Heater for Front (Water Pump) Location

Cylinder Head

Cylinder Head Gasket

Gear Train

Air Compressor

Power Steering Pump

Vibration Damper Hub

Front Cover

Centri-Max Oil Filter Breather Vent

Lubrication System

GLOSSARY OF TERMS

TROUBLESHOOTING

ENGINE SYMPTOM DIAGNOSIS

CAMSHAFT TIMING AND LOBE LIFT CHECKS

Camshaft Timing Check

Camshaft Lobe Lift Check

CHASSIS-MOUNTED CHARGE AIR COOLING TESTS

General Information

Special Tool Required

CMCAC Troubleshooting

CMCAC Pressure Test

Restriction Pressure Test

Core Inspection

CMCAC Preventive Maintenance

CYLINDER HEAD AND CYLINDER BLOCK LEAK TEST PROCEDURE

Cylinder Head and Head Gasket Check — In Chassis

Cylinder Head Fuel Passages Leak Check — In Chassis

Cylinder Block/Cylinder Head Coolant Passages Leak Check — In Chassis

Cylinder Head Oil Passage Leak Check — Out of Chassis

Cylinder Head Coolant Passage Leak Check — Out of Chassis

Cylinder Block Coolant Passage Leak Check — Out of Chassis

ENGINE BRAKE TESTS

Operational Tests

Electrical Troubleshooting

Hydraulic/Mechanical Troubleshooting

Final Test

Troubleshooting Guide

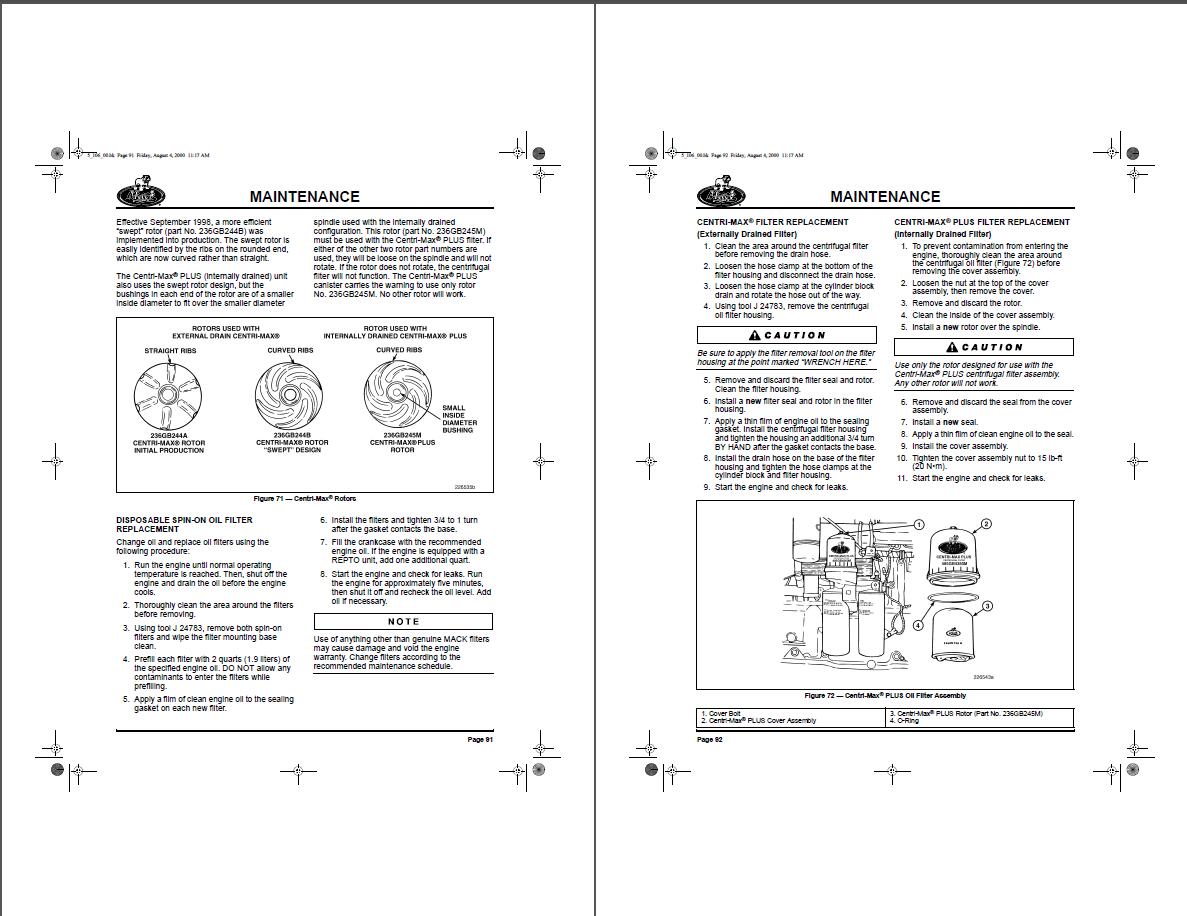

MAINTENANCE

BELT DRIVE SYSTEM TENSIONING

Manually Tensioned System

Automatically Tensioned System

FILTER ELEMENT REPLACEMENT

General Information

Crankcase Breather Filter Cleaning

Oil Filter Element Replacement

Fuel Filter Replacement

Coolant Conditioner Replacement

REPAIR INSTRUCTIONS

ENGINE REMOVAL

General Instructions

Removal from Vehicle

ENGINE DISASSEMBLY

General Instructions

Filter Element Removal

Oil Cooler and Oil Filter Mounting Bracket Assembly Removal

Mounting Engine in Stand

Alternator Removal

Engine Electronic Control Unit (EECU) Removal

Fuel Filter Adapter Assembly Removal

Coolant Conditioner Element Removal

Oil Cooler-to-Water Pump Inlet Line Removal

Thermostat Removal

Coolant Manifold Removal

Air Inlet Manifold Removal

Water Pump Removal

Turbocharger Removal

Fuel Nozzle Inlet Tube Assembly Removal

Exhaust Manifold Removal

Engine Wiring Harness Removal

Engine Electronic Control Unit (EECU) and Cooling Plate Removal

Electronic Unit Pump (EUP) Removal

Oil Fill Tube Removal

Air Compressor Removal

Valve Cover and Spacer Removal

Rocker Arm, Valve Yoke and Push Rod Removal

Nozzle Holder Removal

Cylinder Head Assembly Removal

Vibration Damper and Crankshaft Hub Removal

Oil Pan Removal

Oil Pump Removal

Front Cover Removal

Auxiliary Shaft Removal

Camshaft Removal

Piston and Connecting Rod Assembly Removal

Flywheel Removal

Flywheel Housing Removal

Main Bearing Cap Removal

Crankshaft Removal

CYLINDER BLOCK RECONDITIONING

Special Tools Required

Piston Cooling Spray Nozzle Removal

Cylinder Sleeve Removal

Cleaning and Inspection

Cylinder Sleeve Counterbore

Cup Plug Replacement

Pipe Plug Replacement

H-Ring Replacement

Camshaft Bushing Replacement

Auxiliary Shaft Bushing Replacement

Cylinder Sleeve Installation

Piston Cooling Spray Nozzle Installation

Cylinder Block Dowel Pin Replacement

CRANKSHAFT AND FLYWHEEL BENCH PROCEDURES

General Information

Crankshaft Inspection

Crankshaft Dowel Pin Replacement

Crankshaft Gear Replacement

Crankshaft Wear Ring Installation

Flywheel Inspection and Resurfacing

AUXILIARY SHAFT AND CAMSHAFT BENCH PROCEDURES

Auxiliary Shaft Inspection

Camshaft Inspection

CONNECTING ROD AND PISTON BENCH PROCEDURES

Connecting Rod Inspection and Reconditioning

Piston Inspection and Cleaning

Piston Ring Replacement

Assembling Connecting Rod to Piston

CYLINDER HEAD OVERHAUL

Special Tools Required

Inlet and Exhaust Valve Removal

Cylinder Head Inspection

Fire Ring Groove Cutting

Valve Guide Replacement

Valve Seat Insert Replacement

Valve Spring Inspection

Injection Nozzle Holder Insert Replacement

Valve Yoke Guide Pin Replacement

Cylinder Head Cup Plug Replacement

Cylinder Head Pipe Plug Replacement

Valve Replacement

VALVE ROCKER ARM SHAFT BENCH PROCEDURES

Rocker Arms

Valve Rocker Arm Shaft Disassembly (without/with Engine Brake)

Inspection

Valve Rocker Arm Shaft Reassembly (without Engine Brake)

Valve Rocker Arm Shaft Reassembly (with J-Tech™ Engine Brake)

LUBRICATION SYSTEM BENCH PROCEDURES

Oil Cooler Assembly Reconditioning

Oil Pump Reconditioning

COOLING SYSTEM COMPONENTS BENCH PROCEDURES

Oil Cooler Reconditioning

Water Pump Reconditioning

FUEL SYSTEM COMPONENTS BENCH PROCEDURES

Electronic Unit Pump (EUP) Inspection

Installation of Electronic Unit Pump Plunger Spring and Seat

Fuel Injector Nozzle Cleaning

ENGINE REASSEMBLY

General Instructions

Crankshaft Installation

Main Bearing Cap Installation

Piston and Connecting Rod Installation

Flywheel Housing Installation

Crankshaft Rear Oil Seal Installation

Flywheel Installation

Valve Lifter Installation

Camshaft Installation

Camshaft Core Plug Installation

Camshaft Idler Gear Installation

Auxiliary Shaft Installation

Oil Pump Installation

Front Cover Installation

Crankshaft Front Seal Installation

Crankshaft Hub Installation

Vibration Damper Installation

Oil Pan Installation

Cylinder Head Installation

Exhaust Manifold Installation

Nozzle Holder Assembly Installation

Push Rod Installation

Valve Yoke Installation

Rocker Arm and Engine Brake Installation

Valve Cover and Spacer Installation

Oil Fill Tube Installation

Engine ECU/Cooling Plate Installation

Air Compressor Installation

Electronic Unit Pump Installation

Engine Wiring Harness Installation

Fuel Nozzle Inlet Tube Assembly Installation

Turbocharger Installation

Water Pump Installation

Oil Cooler and Oil Filter Mounting Bracket Installation

Coolant Manifold Installation

Air Inlet Manifold Installation

Thermostat, Housing and Seal Installation

Coolant Conditioner Installation

Fuel Filter Adapter Assembly Installation

Engine ECU Installation

Oil Cooler-to-Water Pump Inlet Line Installation

Alternator Installation

Removing Engine from Engine Stand

Plate-Type Oil Cooler and Oil Filter Mounting Bracket Assembly Installation

ENGINE INSTALLATION

General Instructions

Engine Installation into Vehicle

IN-CHASSIS PART/COMPONENT PROCEDURES

Electronic Unit Pump (EUP) Replacement

Camshaft Replacement (Engine in Chassis)

Engine Brake Control Valve Replacement

Valve Lifter H-Ring Installation Check

ENGINE SETUP AND ADJUSTMENTS

Fuel Injection Timing

Valve Yoke, Valve Lash and Engine Brake Adjustments

Engine Speed and Position Sensors Installation and Adjustment

Electronic Unit Pump (EUP) Calibration

ENGINE FINAL PREPARATION AND OPERATIONAL CHECK

Filter Element Installation

Engine Lubrication System

Turbocharger

Cooling System

Fuel System

Engine Operational Check

REBUILT ENGINE RUN-IN PROCEDURES

General Instructions

Run-In Check

SPECIFICATIONS

E-TECH ENGINE MECHANICAL SPECIFICATIONS

Performance Specifications

Material and Dimensional Data

E-Tech Component Torque Specifications

SPECIFICATION FOOTNOTES

E-TECH™ ENGINE LUBRICANT AND SEALANT SPECIFICATIONS

FASTENER TORQUE

Fastener Selection and Installation

Fastener Sizes and Types

SCHEMATICS & DIAGRAMS

ENGINE SYSTEM SCHEMATICS (FLUIDS FLOW)

Cooling System Flow Diagram

Lubrication System Flow Diagram

Fuel System Flow Diagram

SPECIAL TOOLS & EQUIPMENT

E-TECH ENGINE SPECIAL TOOLS

Special Tools for Engine Overhaul

V-MAC III Special Tools

INDEX

NO shipping cost! Receive your download link via you payment email after payment is being accepted,100% Lifetime Satisfaction Guarantee!

Mitch Wallace –

“It was what I wanted.”

Jeff Rochester –

Very satisfied

Edward Allen –

“Quick manuals”